Very narrow aisle truck - Sideways-seated / tri-lateral stacker 1.2 - 1.5t

Basic Characteristics

– Lift (standard mast): from 3000 - 13000 mm.

– Capacity / load: from 1.20 to 1.5 tons.

- Up to 2 shifts without battery exchange.

- RFID technology.

- Redundant height and weight checks.

- Logistics Interface.

- Expandable to automatic operation – ideal for 3-shift operation.

- Modular design and special build solutions ex-works.

More Characteristics

The ETX 513/515 high rack stackers offer maximum performance in the 'high end area' of a narrow aisle warehouse. They set new benchmarks when it comes to flexibility, efficiency and ergonomics.

Flexibility through modular construction: The Jungheinrich modular system has more than 5 million possible configurations providing flexibility from the outset. The advantage: Optimum adaptation to any warehouse and logistics strategy. An intelligent truck management system with TÜV certified control and CAN-Bus system, means the performance range is adaptable to any requirements and offers a range of additional safety features.

Excellent performance and energy efficiency lead to fast throughput and high cost-effectiveness. This is precisely what is offered by our 3-phase AC technology with higher performance data and greater dynamics, matched by improved energy utilisation. The advantage: Fully usable throughout two shifts in normal operation without battery change. Accessing all these applications is child's play for the ETX operator:

- Informative colour display. Important operating data is easily and legibly laid out.

- All parameters and programs can be set individually.

- Softkeys to control functions and menus.

- Camera/monitor system for effective stacking and retrieval of pallets at great lift heights.

- Hydraulic control by thumb movement.

- Automotive style pedal arrangement for control and braking.

- Side-seated position for fatigue-free operation.

Advantages in Detail

Pioneer of 3-phase AC technology

Over 150,000 Jungheinrich 3-phase AC trucks are in use all over the world.

This depth of knowledge is reflected in today’s drive and control technology:

- Excellent productivity.

- Low energy consumption.

- Effective thermal economy.

- Reduced maintenance and wear.

High throughput levels

- 3-phase AC motors with high torque.

- Excellent acceleration, rapid lift, dynamic ancillary movements.

- Quiet swivelling reach system with high reaching speed.

- Travel direction and height-dependent diagonal travel speed profiles.

- Fast working cycles with synchronised swivel (optional).

Cost-effective energy management

- Doubled energy recovery through regenerative braking and lowering.

- Longer operating times with one battery charge (up to 2 shifts).

- Shorter charging times.

- Active energy / battery management.

- Longer battery life.

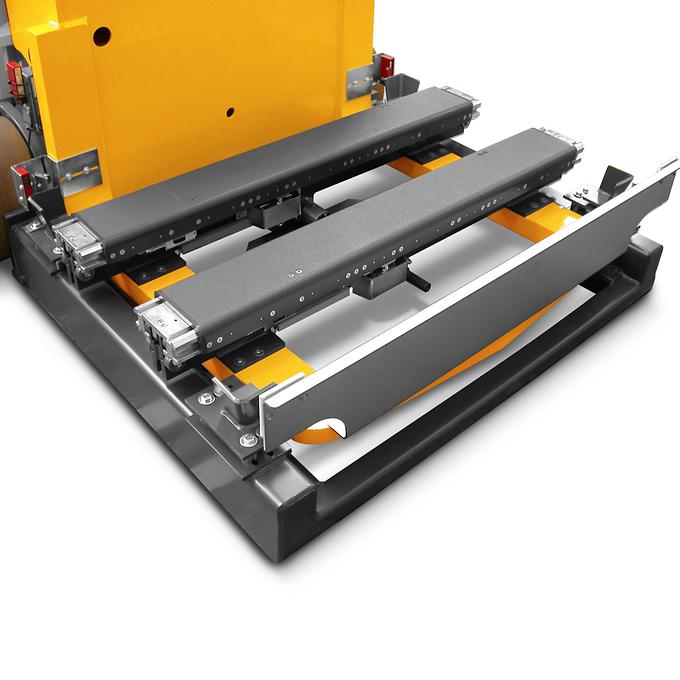

- Battery rollers for rapid battery replacement.

RFID ground control (standard)

- Truck control with transponder technology.

- Permanent route measuring for precise identification of all warehouse areas.

- High flexibility regarding switching and safety functions (end of aisle control, lift/travel cutouts, speed reductions).

- Travel speeds optimised according to the floor topology.

Control and CAN-Bus system

- All functions are adjustable.

- Electronically controlled drive wheel brake and wear-free electromagnetic multi-plate brake on the load wheels (ETX 515).

Commissioning and maintenance

- Quick and reliable commissioning through teach-in process.

- 1000 operating hours service interval.

- Electronics with non-wearing sensor system.

- Gear oil in maintenance-free swing bearing does not require replacement during life of the part.

Reliable operation – high availability

- Robust and maintenance-free 3-phase AC drives with wear-free parts.

- 70% fewer cables and plugs due to CAN-Bus.

- Extremely torsion-resistant mast for high residual capacities and low mast sway.

warehouseNAVIGATION (optional)

- Linking the ETX to a warehouse management system (WMS) via radio data terminal or scanner.

- Direct acceptance of the destination in the narrow aisle by the truck computer.

- Automatic vertical positioning.

- Automatic horizontal position control system.

- Automatic stacking operation.

- Effective twin cycles.

- RFID location detection prevents trucks travelling to incorrect destinations.

- Maximum flexibility in the warehouse, as the existing WMS can be modified to cater for warehouse extensions.