Reach truck - Multi-directional reach truck 2.0 - 2.5t

Basic Characteristics

– Lift (standard mast): from 4250 - 10700 mm.

– Capacity / load: from 2.00 to 2.50 tons.

- Electronically controlled all-wheel steering.

- Generously designed operator workplace.

- curveCONTROL for optimum travel safety.

More Characteristics

Multi-directional reach trucks are used wherever long loads are transported in narrow aisles and need to be elevated to extreme heights. With electric all-wheel steering, loads up to 8m long can be transported optimising use of available space.

There are 5 steering modes available ranging from enhanced normal travel and turning on the spot, through to transverse and parallel travel. In 'enhanced normal travel', the already small turning radius is reduced further by simultaneous load wheel steering. The advantages of 360° steering are also available: Minimum turning radius and rapid direction change. This makes the ETV Q clearly superior to any conventional 4-way reach truck.

Uncomplicated, intuitive handling with ergonomically arranged displays and controls as well as outstanding visibility makes operating the truck simplicity itself. In addition, assistance systems increase productivity:

- Jungheinrich curveCONTROL reduces the maximum travel speed when cornering, depending on the steer angle.

- Weighing systems allow weights to be checked at the press of a button.

- Mast reach cushioning reduces mast sway during stacking and retrieval operations, thereby increasing throughput.

The outstanding performance is complemented by excellent cost-effectiveness:

- More pallet throughput thanks to greater travel and lift performances.

- Long operating times thanks to the reduction in energy consumption with the same throughput.

- Less aisle width required as a result of the proven reach principle.

A number of options and battery versions ranging from 620 Ah to 930 Ah ensure that the trucks can be adapted to any application.

Advantages in Detail

Safety

- Electric brakes on all 3 wheels ensure that the ETV Q stays in the lane when braking during sideways movement.

- Optional reversing camera provides a better view during sideways travel in reverse.

- Optional panorama roof provides a clear view of the raised load.

High-performance mast

Our masts ensure maximum safety and effective utilisation of warehouse capacity at extreme heights:

- Lift heights up to 10,700 mm.

- Low clearances at high lift heights.

- Extremely long life through cold-rolled mast sections.

- High residual capacities even at extreme lift heights.

- Optional, patented mast-reach cushioning reduces mast sway when stacking and retrieving.

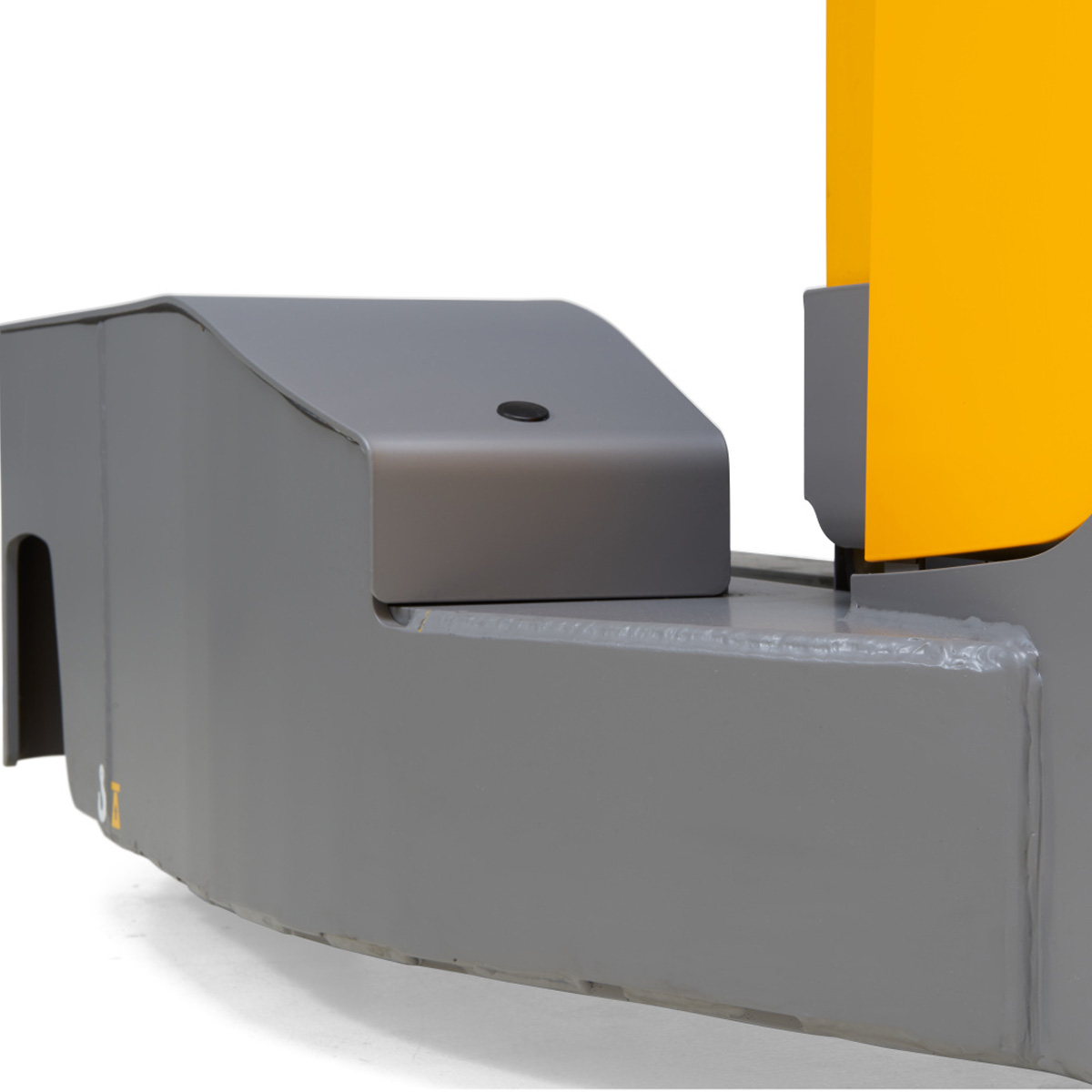

Fork positioner with extended fork shank (optional)

Optimum adaptation for different load widths for the safe transportation of long loads:

- Easy adjustment at the press of a button.

- Straddle width up to 2060 mm.

- Integrated design with short chassis length for narrow aisle widths.

- 3 versions with different frame widths available.

Ergonomic workstation

Maximum performance due to the comfort of an ideal operator's seat:

- 5 buttons for simple and fast selection of the steering modes.

- Comfort seat, fully adjustable for all operators (seat position, backrest, bodyweight).

- Plenty of storage options.

- Generous space.

- 3-phase steering of all 3 wheels can be changed from 180° to 360°.

- Automotive layout of the pedals.

Assistance systems and options

For more power and full load stability:

- operationCONTROL continuously measures the load weight and compares it with the residual capacity of the truck. An optical warning on the operator display as well as an acoustic warning are triggered when approaching the limit value.

- positionCONTROL with SNAP function enables simple and fast stacking without additional pressing of buttons.

- liftNAVIGATION transfers stacking orders automatically from the warehouse management system, preventing stacking errors.

- Fork camera and ergonomically adjustable motor enable especially safe and efficient stacking and retrieval.

soloPILOT control lever

The control lever for activating all hydraulic functions is also used for selecting the direction of travel and activation of the horn:

- All controls are within the operator's field of vision and a single function is clearly assigned to each one.

- Maximum handling capacity through the simultaneous use of 2 hydraulic functions (e.g. lifting and reaching).

- Convenient control of additional attachments, e.g. a fork positioner (optional).

- Precision operation by sensitive activation of all functions.

- Comfortable posture with padded armrest.

- multiPILOT (optional).

Easy-to-read colour display

- Display of direction of travel and wheel position.

- Battery status with residual time display.

- 3 adjustable travel programs for individual adjustment to any requirements.

- Operating hours and time of day.

- Lift height (optional).

- Load weight (optional).

Lithium-ion technology

The EJC offers plenty of storage space for a tidy workplace:

- High degree of availability thanks to extremely short charging times.

- No battery exchange required.

- Cost savings due to longer service life and low maintenance compared with lead-acid batteries.

- No charging rooms and ventilation required as there is no build up of gas.

- Longer service life with 5-year Jungheinrich guarantee.